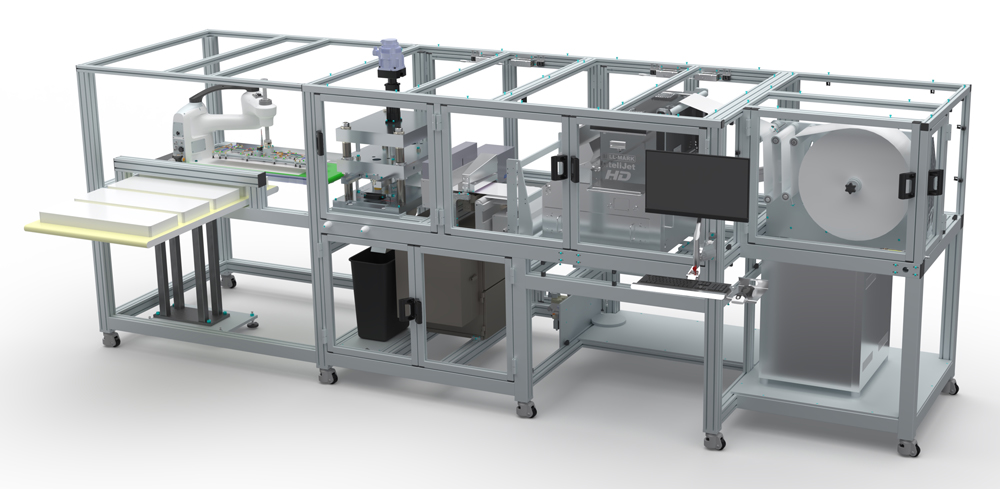

Application

On demand printing and cutting of Tyvek® lid eliminates the need to purchase pre-cut, pre-printed lids. Ideal for high SKU, low or mid-range volume applications.

Packaging Materials

Material input rollstock lidding.

Tyvek® or Medical Paper.

- Benefits of producing pre-printed lids in-house

- Significant cost savings vs sourcing

- Just in time production vs stocking

- Streamline operations to actual customer demand

- Less than 1% Tyvek scrap vs traditional methods

- Print online lot and expiration – no secondary printing needed

- Lids can be produced in bulk for later use or robotically placed directly to SelectSeal medical compliant tray sealer

- Numerous cut profile geometries with a 10-minute die change

- Simple tool change

- Class 8 cleanroom compatible

- Vision inspection of device, Tyvek® graphics and variable data

- Recipe scan to load with auto tool verification

- Fully validatable, GMP Compliant

- Open software architecture

Machine Specifications

| Typical Configuration | Other Configurations | |

|---|---|---|

| Max Web Format (web width x index) | 11″ x 32″ (280mm x 813mm) | Smaller formats readily vailable |

| Rollstock (Top) | 14” (356mm) max dia roll, 3” (76mm) core | Larger diameter roll unwind options available |

| Web Cleaning System (optional) | 2-hood system or no web cleaning | 4 hood web cleaning system and anti-static bars by Static Clean International |

| Web Edge (optional) | Coast Controls web edge guiding system | Edge detection within 0.5mm with alarm |

| Rate | Up to 20 Cycles per minute (CPM) | |

| Materials of Construction | Anodized Aluminum Extruded framework, SS, other cleanroom compatible materials | |

| Power (utility) | 240VAC or 480VAC, 3phase, 60hz | Other voltages available |

| Air Consumption (utility) | 80-100PSI air source, CFM to be provided based on actual application | |

| Film Unwind | Powered, constant tension with low roll, web break and splice detect as standard | Dual roll unwind or cart |

| Top Web Print | Online digital UV printing, artwork per recipe | All print technologies can be provided |

| Cutting | Matched metal round corner cutting, changeout trim cartridge | |

| Final Lid Output Configuration | Lids are stacked in preset quantity on accumulation conveyor, rejected lids are collected in bin | Other output configurations available |

| Controls | Allen-Bradley PLC and HMI with Yaskawa motion | Other platforms available upon request |

| Safety | Zero tolerance safety package | |

| Vision | Cognex or Keyence cameras for inspection of printed graphical and variable information | |

| Software Features | Process parameter verification, 4 User security logins, Data change tracking, Line Clearance | Customizable per requirements |