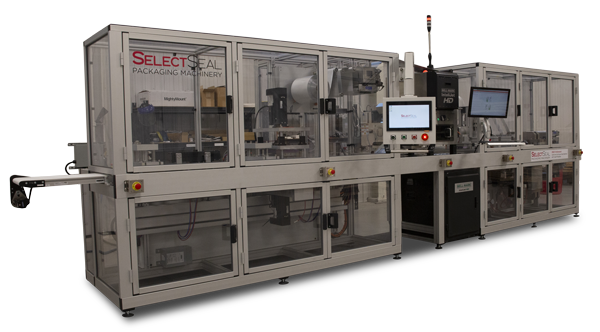

Application

The 290CF OnDemand HFFS Cold Form Suture Pack Machine is ideal for foil /foil suture packs that require a Tyvek® breather for sterilization process. Eliminates the need for a secondary breather package. Ideal for high SKU, low or mid-range volume applications. Use this machine in conjunction with SelectSeal Post Sterilization Seal/Trim Machine.

Packaging Materials

Material input rollstock lidding

Cold Formable Foil, Foil Lidding and Tyvek ®

- High force forming with air pressure

- In-line on-demand full color printing

- Print online lot and expiration – no secondary printing needed

- Servo-based sealing with direct force feedback verification

- Minimal scrap of high cost foil material

- Precision hole locations for secondary processing

- Simple tool change

- Class 8 cleanroom compatible

- Vision inspection of device, graphics and variable data

- Recipe scan to load with auto tool verification

- Fully validatable, GMP Compliant

- Open software architecture

Machine Specifications

| Typical Configuration | Other Configurations | |

|---|---|---|

| Max Web Format (web width x index) |

11.4″ x 4.7″ (290mm x 120mm) | Other formats readily available |

| Rollstock (Top and Bottom) | 14” (356mm) max dia roll, 3” (76mm) core | Larger diameter roll unwind options available |

| Rollstock (Tyvek®) | 14” (356mm) max dia roll, 3” (76mm) core | Larger diameter roll unwind options available |

| Web Cleaning System (optional) | 2-hood system or no web cleaning | 4 hood web cleaning system and anti-static bars by Static Clean International |

| Web Edge | Coast Controls web edge guiding system | Edge detection within 0.5mm with alarm |

| Rate | Up to 20 Cycles per minute (CPM) | |

| Materials of Construction | Anodized Aluminum Extruded framework, SS, other cleanroom compatible materials | |

| Power (utility) | 240VAC or 480VAC, 3phase, 60hz | Other voltages available |

| Air Consumption (utility) | 80-100PSI air source, CFM to be provided based on actual application | |

| Film Unwind | Powered, constant tension with low roll, web break and splice detect as standard | Dual roll unwind or cart |

| Form Station | High force forming station with air pressure forming. Form air up to 170 PSI available. No mechanical plugs. | |

| Pin Hole Detection (optional) | Space available | Pinhole creation and pinhole detection systems available. |

| Cutting – Breather Hole | Matched metal round corner trim of breather area | |

| Top Web Print | Online digital UV printing, artwork per recipe | Number of colors can be specified |

| Cutting – Locating Hole | Matched metal hole punches trim with vacuum slug removal | |

| Controls | Allen-Bradley PLC and HMI with Yaskawa motion | Other platforms available upon request |

| Seal Station | 3000# max force, servo-based sealing station with direct force load cell feedback for verification. Seal force calibration kit included. | Pneumatic-based sealing available |

| Cutting – XMD | Matched metal straight cut of 4up suture sheet | |

| Final Output Configuration | 4up sheet with sutures, pre-sealed perimeter with connection to breather, Tyvek® breather sealed to bottom web. | Other output configurations available |

| Controls | Allen-Bradley PLC and HMI with Yaskawa motion | Other platforms available upon request |

| Safety | Zero tolerance safety package | |

| Vision | Cognex or Keyence cameras for inspection of printed graphical and variable information | |

| Software Features | Process parameter verification, 4 User security logins, Data change tracking, Line Clearance | Customizable per requirements |