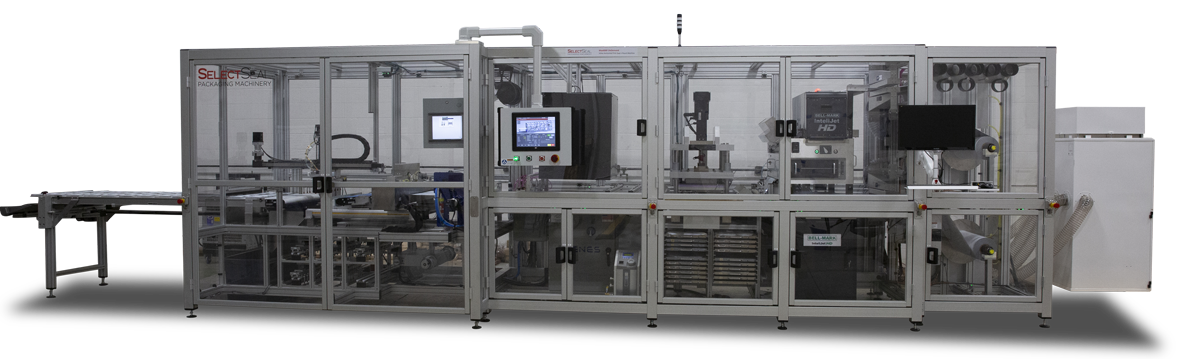

SelectSeal Max600F

Inline Horizontal 3-Side Seal • Pouch Machine

Application

The Max600F is used to produce 3-side-seal and printed pouches from two layers of rollstock that are used for finished goods medical packaging. This machine is ideal for high volume, high SKU requirements in a clean room manufacturing environment. With the ability to run various film structures, online printing and quick-change seal tooling, the Max600F provides the most flexibility in producing pouches – on-demand for medical device manufacturers. Up to 24” wide format allows for a wide range of pouch sizes.

Packaging Materials

Rollstock Non-Forming Films: Heat sealable Tyvek®

Medical Paper, Foil or Poly Films

- Up to 24” wide web.

- 24” x 12.5” format for die lines.

- On-line digital printing.

- Medical web cleaning system.

- Quick-Change Seal tooling

- Servo-based and automatic adjustments on tool-recipe change

- On-machine tool storage.

- Bar code verification of seal tool to recipe.

- Print inspection of graphical and variable information per recipe.

- Servo-based seal station with direct loadcell feedback.

- Adaptable design allows varied packaging sizes and features.

- Simple tool change. No water, wiring or reheating required.

- Class 8 cleanroom compatible.

- Open software architecture, native software files included.

- Allen-Bradley CompactLogix Processor with 12” PanelView Plus color touchscreen.

- Fully validatible, GMP Compliant.

Machine Specifications

| Typical Configuration | Other Configurations | |

|---|---|---|

| Max Web Format (web width x index) |

24” x 12.5” (610mm x 318mm) | Smaller format readily available |

| Rollstock (Top and Bottom) | 24” (610mm) max dia roll, 3” (76mm) core | 6” (152mm) dia core available |

| Web Cleaning System | 4 hood web cleaning system and anti-static bars by Static Clean International |

2-hood system or no web cleaning |

| Web Edge | Edge detection within 0.5mm with alarm | Optional auto web guiding system |

| Rate | 3 – 20 Cycles per minute (CPM) | |

| Materials of Construction | Anodized Aluminum Extruded framework, SS, other cleanroom compatible materials |

|

| Power (utility) | 240VAC or 480VAC, 3phase, 60hz | Other voltages available |

| Air Consumption (utility) | 80-100PSI air source, CFM to be provided based on actual application |

|

| Film Unwind | Powered, constant tension with low roll, web break and splice detect as standard |

Dual roll unwind or cart |

| Top Web Print | Online digital UV printing, artwork per recipe Eyemark registration for pre-printed top film |

All print technologies can be provided |

| Seal Station | 3700# capacity servo based sealing station with direct force load cell feedback for verification. |

Pneumatic driven sealing available |

| Tear Slit | Manually adjustable tear slit system with 5 knife positions | Auto adjust available Tear notch die available |

| Machine Direction Cutting (MD) | Crush cut system, equipped with 10 knives that automatically adjust cut position based on recipe | Other cut systems available |

| Across Machine Direction Cutting (XMD) | Azco feed/cut system with guillotine knife and high precision feed roller drive system |

|

| Final Pouch Output Configuration | Single row output with reject row dump conveyor | Pouch spread and stacking systems available |

| Controls | Allen-Bradley PLC and HMI with Yaskawa motion | Other platforms available upon request |

| Safety | Zero tolerance safety package | |

| Vision | Cognex or Keyence cameras, graphical print verification | |

| Software Features | Process parameter verification, 4 User security logins, Data change tracking, Line Clearance |

Customizable per requirements |